Unmatched Chemical and Temperature Resistance in Demanding Environments

PTFE Resistance to Gasoline, Ethanol, and Aggressive Automotive Fluids

PTFE tubes are really good at standing up to chemicals without breaking down, even when they come into contact with things like gasoline, various ethanol mixtures from E10 to E85, and transmission fluids. The reason PTFE doesn't swell or get brittle around hydrocarbon solvents has to do with how its molecules are arranged differently compared to materials like rubber or nylon. According to testing done recently by Industrial Spec, PTFE samples kept about 98% of their original tensile strength after sitting in methanol at 80 degrees Celsius for a thousand hours straight. That's actually pretty impressive since regular FKM rubber would lose around 28% under similar conditions. For automotive engineers working on fuel vapor management systems or urea injection components in today's cars, this kind of durability makes all the difference between reliable performance and premature failure.

Performance Stability Across Extreme Temperatures (-200°C to +260°C)

PTFE's fluoropolymer bonds give it both chemical resistance and the ability to work well across a wide temperature range, from super cold environments all the way up past 200 degrees Celsius. According to recent findings from Global O-Ring in their 2023 study, PTFE maintains around 91% of its flexibility even when temperatures drop to minus 50 degrees, while nylon loses about 64% of its flexibility under similar conditions. When tested for thermal cycling, brake hoses lined with PTFE didn't show any fluid leakage at 230 degrees Celsius, which is actually 63 degrees hotter than what the Department of Transportation requires as a minimum standard. This kind of performance really stands out when materials are subjected to extreme heat changes during operation.

Case Study: PTFE in Turbocharged Engines and High-Heat Under-Hood Applications

A 2023 analysis of twin-scroll turbo systems found that PTFE charge air cooler tubes reduced heat soak by 18% versus silicone counterparts. The material's thermal stability prevents softening during sustained 2.5-bar boost conditions, maintaining precise airflow control even after 500 thermal cycles—a critical advantage in high-performance powertrains.

Limitations in Biofuels With Reactive Additives: A Niche but Growing Concern

While PTFE resists conventional biodiesel (B20), newer bio-additives containing methyl esters exhibit 12% higher permeation rates in accelerated aging tests. To address this, manufacturers are incorporating composite liners with PFA layers, which reduce additive interaction by 60% at 90°C operating temperatures—ensuring compatibility with next-generation renewable fuels.

Low Friction and High Flow Efficiency in Fluid Delivery Systems

PTFE tubes significantly enhance fluid system efficiency through their low friction coefficient (0.04–0.10), minimizing turbulence in fuel and hydraulic lines. A 2023 study by Wu et al. in Energy demonstrated that PTFE-lined fuel lines improved flow rates by 18–22% compared to nylon, reducing pumping energy demands by 12–15% in high-pressure direct injection systems.

How PTFE's Low Friction Coefficient Improves Fuel and Hydraulic Flow Dynamics

The almost non-existent stickiness of PTFE means fuel additives and hydraulic fluids don't cling to the inside of tubes, so they keep flowing smoothly even when pressure reaches 3,500 psi. A study done by Ling and others back in 2014 found that because PTFE has such a smooth surface (roughness below 0.8 microns), it cuts down on drag in transmission oil coolers by about 40 percent compared with regular rubber hoses. For electric vehicles that need spot-on temperature control, this kind of consistency really matters. Just a 5% change in flow rate can actually mess up how well batteries stay cool during operation.

Strategy: Enhancing Pump Efficiency With Smooth-Bore PTFE Linings

Car manufacturers have started putting thin wall PTFE linings inside those high pressure fuel pumps to cut down on internal friction issues. A recent study published by MDPI looked at hydraulic systems back in 2023 found that when they used 0.5mm thick PTFE linings in these pumps, there was about an 83% drop in wear particles after running through 100 thousand cycles. What's more impressive is that flow remained stable within plus or minus 1.2 percent even when RPMs fluctuated around. The real benefit here? These pumps last 2 to 3 times longer between maintenance checks than their metal or composite counterparts. Makes sense why the auto industry is pushing for this change as part of broader moves toward better efficiency in managing fluids across modern vehicle powertrains.

Superior Mechanical Strength and Pressure Handling Capabilities

Reinforced PTFE tubes offer outstanding mechanical performance, making them ideal for automotive systems operating under extreme pressure. Their molecular structure and advanced reinforcement techniques ensure reliable operation where conventional materials fail.

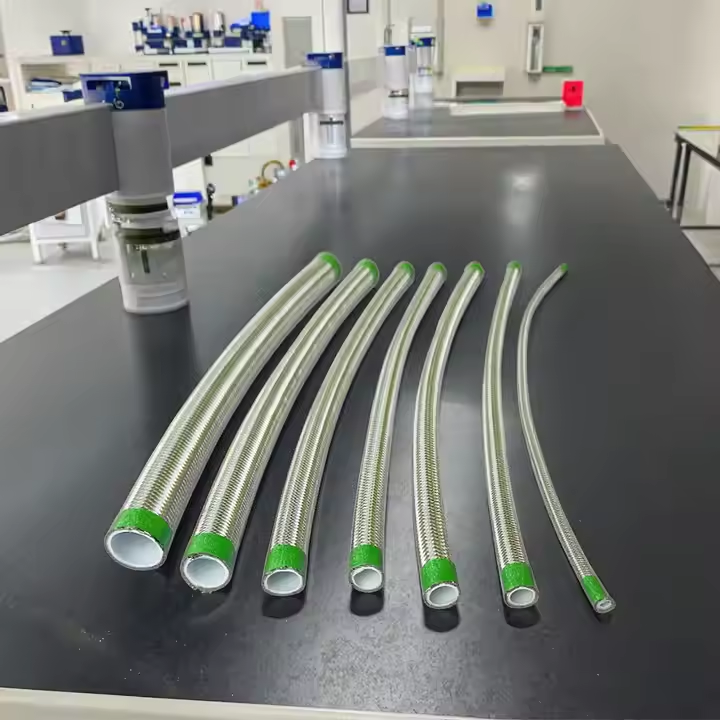

High Burst Pressure Ratings (Over 5,000 PSI) in Reinforced PTFE Hoses

PTFE hoses that have multiple layers and stainless steel braiding can handle burst pressures over 5000 psi, which is about 60 percent better than what rubber hoses offer. The reason for this kind of strength lies in how PTFE naturally holds up under stress combined with the special helical wire wrapping technique used during manufacturing. Industry research shows that these types of hoses work well for around 9 out of 10 high pressure situations found in automotive systems. They don't need those thick walls that other materials require, so engineers get to design parts that are both lighter and take up less space on vehicles.

Application in Power Steering, Braking, and High-Pressure Hydraulic Systems

Modern brake-by-wire systems rely on PTFE tubing to withstand 3,000–4,500 psi fluid pulses without fatigue. Its radial strength eliminates dangerous ballooning in power steering lines during aggressive maneuvers. In dual-clutch transmissions, PTFE maintains seal integrity at 80 bar—pressures that cause deformation in nylon lines.

Long-Term Durability and Reduced Maintenance Compared to Rubber or Nylon

Tests on accelerated aging reveal that PTFE fluid lines hold about 92% of their original burst strength even after a decade, while rubber only manages around 67%. What makes PTFE stand out is its resistance to moisture absorption unlike nylon which tends to soak it up. This means PTFE maintains its mechanical integrity even when exposed to damp conditions over time. Real world testing across fleets has shown these lines last roughly three times longer between replacements, translating into about $18 saved annually per vehicle according to findings published in Fluid Systems Journal back in 2023. While PTFE comes with a steeper price tag initially, these long term savings make it worth considering for operations looking at total lifecycle costs rather than just upfront expenses.

Critical Role in Automotive Safety and System Reliability

PTFE tubes offer important safety benefits for those crucial parts of cars where things really matter. When used in brake systems, these tubes absorb almost no moisture at all (less than 0.01% even when exposed to high humidity conditions). This property stops the brake fluid from breaking down over time. A study published in 2023 by TMC Solutions found that degraded brake fluid actually contributes to about 17% of all brake failure cases. The material's stability means brakes maintain proper pressure throughout thousands upon thousands of stopping events in modern ABS systems without losing effectiveness.

When it comes to fuel delivery systems, PTFE has a major advantage because its structure is completely free of pores. This basically stops hydrocarbons from leaking through, which cuts down emissions by around 78% when compared with regular nylon lines according to SAE standards from 2024. Car manufacturers are increasingly going for PTFE lined hoses these days, especially for those high pressure direct injection systems that run at over 220 bar pressures. Sure, PTFE costs anywhere between three to five times what rubber does, but look at the long term picture. These materials last about 15 years in engine compartments where temperatures get really hot, so they actually pay for themselves through improved safety over time. The material can handle stresses up to 25 MPa even at 200 degrees Celsius, making unexpected hose failures almost unheard of. And let's face it, sudden hose bursts are responsible for roughly 43% of all fluid related vehicle recalls as reported by NHTSA back in 2022.

Growing Adoption Across Conventional and Electric Vehicle Platforms

The automotive sector keeps moving forward, and PTFE tubes have become essential components in both traditional internal combustion engines and newer electric vehicles. Electric car sales are expected to hit around 30% of all passenger vehicles sold worldwide by 2032 according to recent research from RMI. This makes sense when we look at what PTFE offers: excellent dielectric properties and strong resistance to corrosion. These characteristics make it particularly valuable for managing heat in high voltage batteries and protecting sensitive power electronics. Traditional rubber materials just can't match this performance. PTFE doesn't create dangerous electrical arcs and holds up against harsh chemicals found in lithium-ion batteries as well as various thermal management fluids used throughout modern vehicles.

Expanding Use in EVs: Dielectric Insulation and Corrosion Resistance Needs

Electric vehicle designs need special materials that can handle high voltage systems above 800 volts plus deal with harsh chemical environments. Polytetrafluoroethylene, or PTFE for short, doesn't conduct electricity so it stops unwanted current leaks in coolant lines right next to motor control units. Plus, its stable molecular structure stands up against formic acid which forms when biodegradable coolants break down over time. Most car makers have started using PTFE lined hoses as part of their battery cooling systems these days because if something goes wrong with those systems, we're talking about serious fire risks that nobody wants to deal with on the road.

Trend: Shift From Rubber/Nylon to PTFE in Next-Gen Fluid System Design

Car manufacturers have noticed around 40 percent fewer warranty problems after switching from nylon to PTFE fuel lines in areas where temperatures get really extreme. One big advantage of PTFE is how little moisture it absorbs compared to rubber brake hoses which tend to swell up when things get damp and hot. With electric vehicles generating less heat under the hood these days, the fact that PTFE remains flexible even at minus 200 degrees Celsius becomes super important for sensor reliability on roads treated with salt during winter months. Because PTFE works well both in traditional combustion engines and newer electric models, we're seeing increased interest in these tubes. Market research suggests demand will grow at roughly 9.3% year over year until 2030 as automotive companies continue this transition.

Frequently Asked Questions (FAQ)

What is PTFE and why is it used in automotive applications?

PTFE, or polytetrafluoroethylene, is a type of fluoropolymer known for its exceptional chemical resistance and ability to withstand extreme temperatures. In the automotive sector, it is used due to its ability to handle aggressive automotive fluids and maintain performance in high-pressure systems.

How does PTFE resist chemical and temperature changes?

PTFE's molecular structure allows it to resist swelling and brittleness when exposed to hydrocarbon solvents and extreme temperatures. It can maintain flexibility and tensile strength under harsh conditions, making it suitable for fuel vapor management systems and turbocharged engines.

Are there any limitations to using PTFE with biodiesel?

While PTFE is mostly resistant to B20 biodiesel, newer bio-additives containing methyl esters have shown higher permeation rates. Manufacturers are addressing this by incorporating composite liners with PFA layers to ensure compatibility with modern biofuels.

What are the benefits of PTFE's low friction coefficient?

PTFE has a low friction coefficient that reduces drag and turbulence, improving flow rates and efficiency in fuel and hydraulic systems. This characteristic is especially beneficial for high-pressure injection systems and maintaining consistent cooling in electric vehicles.

How does PTFE contribute to automotive safety?

PTFE absorbs minimal moisture, helping brake systems maintain their effectiveness over time. It prevents leakages and reduces emissions compared to nylon, enhancing the reliability and safety of automotive fluid delivery systems.

Why are manufacturers shifting from rubber/nylon to PTFE?

Manufacturers are increasingly adopting PTFE for its superior resistance to extreme temperatures, reduced moisture absorption, and enhanced durability. These qualities provide long-term savings and reliability, especially in environments with fluctuating temperatures.

Table of Contents

- Unmatched Chemical and Temperature Resistance in Demanding Environments

- Low Friction and High Flow Efficiency in Fluid Delivery Systems

- Superior Mechanical Strength and Pressure Handling Capabilities

- Critical Role in Automotive Safety and System Reliability

- Growing Adoption Across Conventional and Electric Vehicle Platforms

-

Frequently Asked Questions (FAQ)

- What is PTFE and why is it used in automotive applications?

- How does PTFE resist chemical and temperature changes?

- Are there any limitations to using PTFE with biodiesel?

- What are the benefits of PTFE's low friction coefficient?

- How does PTFE contribute to automotive safety?

- Why are manufacturers shifting from rubber/nylon to PTFE?