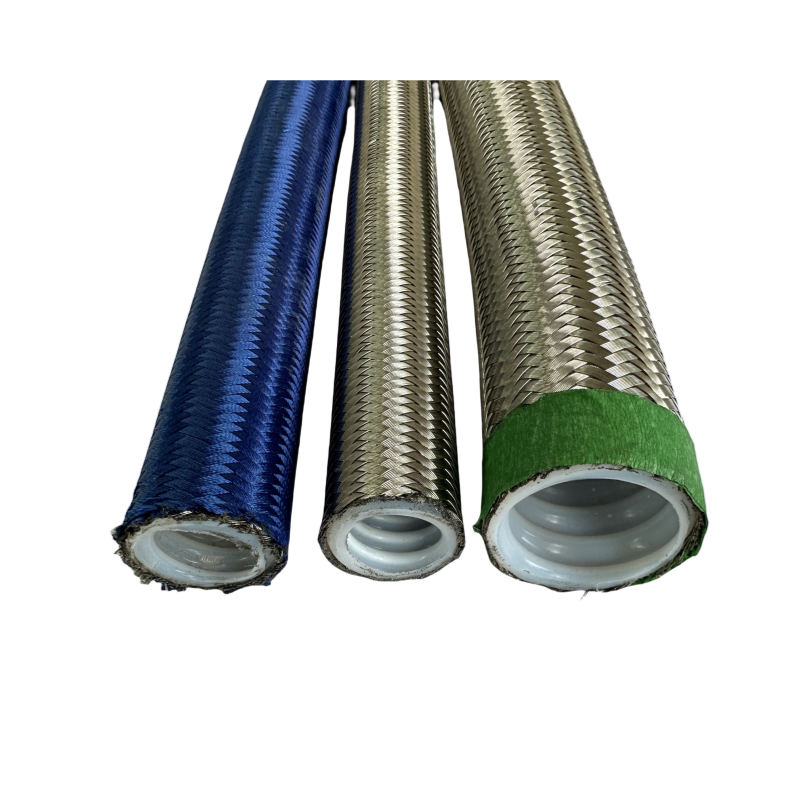

Teflon Flexible Hose: Ideal for Flexible Pipelines

The Teflon flexible hose emphasizes its soft and bendable characteristics. It is suitable for pipeline systems that require flexible layout. Its Teflon material also provides good chemical resistance, making it applicable in various industries where flexibility and chemical stability are both needed, such as in some laboratory equipment and small - scale chemical processing setups.

Get A Quote