الخصائص غير اللاصقة لأنابيب التفلون في التعامل مع السوائل في صناعة أشباه الموصلات

كيف تمنع أسطح أنابيب التفلون التصاق الجسيمات أثناء نقل السوائل؟

تتميز أنابيب التفلون بأسطح ناعمة جدًا لدرجة أن قياسها أقل من 0.1 على مقياس الاحتكاك وفقًا لمعايير ASTM. وهذا يسمح للمواد الكيميائية مثل المذيبات، والمحاليل الأكيلة، وحتى المياه الفائقة النقاء بالتدفق من خلالها تقريبًا بدون أي مقاومة تُذكر. وسر هذه الخاصية غير اللاصقة الاستثنائية يكمن في التركيب الجزيئي لـ PTFE. فعند النظر إليها عن كثب، فإن الروابط القوية بين الكربون والفلور تُشكّل حاجزًا يدفع بشكل حرفي الشوائب والجسيمات غير المرغوب فيها بعيدًا على المستوى المجهري. ويستفيد مصنعو أشباه الموصلات بشكل كبير من هذه الخاصية في غرف التنظيف الخاصة بهم. إذ أثناء عمليات نقل المواد الكيميائية، تلتصق عدد أقل بكثير من الجسيمات النانوية بجدران أنابيب التفلون الداخلية مقارنةً ببدائل السيليكون العادية. وتدعم الدراسات المنشورة في مجلة تقنية غرف التنظيف هذا الاستنتاج، حيث تُظهر انخفاض مستويات التلوث بنحو النصف تقريبًا عند استخدام هذه الأنابيب المتخصصة مقارنةً بالبدائل التقليدية.

الخصائص الكارهة للماء ومنخفضة الاحتكاك لـ PTFE في بيئات الغرف النظيفة

بوليتيترافلوروإيثيلين، أو ما يُعرف اختصارًا بـ PTFE، يتمتع بخصائص طاردة للماء بشكل طبيعي. فزاوية تلامس الماء معه تتجاوز 110 درجات، مما يجعله فعالًا جدًا في منع السوائل من الالتصاق بالأسطح، وهي خاصية مهمة جدًا في العمليات الحساسة لمستويات الرطوبة مثل التطبيقات المستخدمة في التصوير الضوئي. وعند النظر إلى مدى انخفاض طاقة سطح مادة PTFE الفعلية، والتي تتراوح بين 18 و22 ملي نيوتن لكل متر، نجد أن المواد تنزلق بسهولة من على السطح ولا تلتصق به. وهذا يعني أنه لا حاجة لاستخدام مواد كيميائية قاسية للتنظيف، لأن أي شيء يصعب التصاقه بالسطح أصلًا. فما الذي يجعل مادة PTFE ذات قيمة كبيرة في غرف التنظيف النقي المعتمدة حسب المعيار ISO Class 1؟ حسنًا، أظهرت الاختبارات أن أنابيب PTFE يمكنها الحفاظ على عدد الجسيمات أقل من خمسة جسيمات لكل مليلتر بالنسبة للجسيمات الأكبر من 0.1 ميكرومتر، حتى بعد مرور مواد كيميائية من خلالها باستمرار لمدة 500 ساعة متواصلة. هذا النوع من الأداء يدل دلالة واضحة على موثوقية المادة في الحفاظ على بيئات شديدة النقاء.

تأثير الأداء غير اللاصق على نقاء العملية والإنتاجية

تمنع أنابيب التيفلون تراكم الجسيمات داخل الأنظمة، وهو أمر ضروري للوصول إلى معايير النقاء القريبة من الكمال بنسبة 99.999% المطلوبة عند تصنيع الشرائح الأصغر من 5 نانومتر. شهد أحد مصانع أشباه الموصلات انخفاضًا في الألواح العمياء المعيبة بنحو 32٪ بعد استبدال الأنابيب القديمة بأنابيب نقل سوائل من مادة PTFE. هذا النوع من التحسن يُظهر بوضوح مدى أهمية هذه المواد بالنسبة للإنتاجية. وميزة كبيرة أخرى؟ طبيعة مادة PTFE غير التفاعلية تعني أنها لن تتداخل مع العلاجات الكيميائية الحساسة أثناء خطوات التصنيع. وهذا يمنع حدوث مجموعة من التفاعلات الكيميائية غير المرغوب فيها التي قد تفسد دفعات كاملة من ألواح السيليكون أثناء المعالجة.

المقاومة الكيميائية ومتانة أنابيب PTFE في العمليات القاسية

أداء أنابيب التيفلون مع مواد التنقية العدوانية مثل HF وHCl

تعمل أنابيب البولي تيترافلوروإيثيلين (PTFE) بشكل جيد حقًا مع عوامل التآكل القوية للغاية مثل حمض الهيدروفلوريك (HF) وحمض الهيدروكلوريك (HCl). وفقًا للاختبارات الصناعية، يحتفظ البولي تيترافلوروإيثيلين بنسبة 99.8% تقريبًا من وزنه الأصلي حتى بعد بقائه في حمض الهيدروكلوريك المركز لمدة 500 ساعة عند درجة حرارة حوالي 80 مئوية. وهذا أفضل بكثير من الخيارات مثل كلوريد متعدد الفينيل (PVC)، الذي يفقد عادةً ما بين 40 إلى 60 بالمئة تحت ظروف مماثلة. والسبب وراء هذه المتانة المثيرة للإعجاب؟ يتمتع البولي تيترافلوروإيثيلين بهيكل جزيئي مفلور بالكامل، مما يجعله في الأساس محصنًا ضد معظم التفاعلات الكيميائية وتبادل الأيونات. فهو لا يتفاعل مع المواد الأخرى بالطريقة التي تتفاعل بها المواد الأخرى.

الخواص الكيميائية الخاملة للبولي تيترافلوروإيثيلين (PTFE) في ظل الظروف الشديدة الحرارة والقابلة للتآكل

لا يتفاعل التفلون كيميائيًا حتى في الظروف القاسية. وهو يعمل بشكل جيد في درجات حرارة تتراوح من سالب 70 درجة مئوية حتى 260 درجة مئوية، ويمكنه تحمل ضغط يصل إلى 300 رطلاً لكل بوصة مربعة. تُظهر الاختبارات أنه لا توجد أي تسربات على الإطلاق عند التعرض لأبخرة حمض الكبريتيك عند حوالي 250 درجة مئوية. كما لا تُظهر المادة أي علامات تآكل بعد الخضوع لما يقارب ثلاثة آلاف دورة تسخين وتبريد. هذه الخصائص تجعل التفلون مناسبًا بشكل خاص للمهام الصناعية الصعبة مثل عمليات الترسيب الكيميائي للبخار ومعدات النقش البلازمي. وفي هذه التطبيقات، غالبًا ما تتغير درجات الحرارة بأكثر من 200 درجة مئوية كل دقيقة واحدة.

الموثوقية طويلة الأمد لـ PTFE في التعرض المستمر لعمليات أشباه الموصلات

تؤكد دراسات الشيخوخة المُسرَّعة التي تحاكي أكثر من خمس سنوات من التعرض لمراهم الطلاء الكهربائي للنحاس ومحاليل إزالة الطلاء الضوئي أن مادة البولي تيترا فلورو إيثيلين (PTFE) تحتفظ بـ 95٪ من قوتها الشدّية وتُظهر أقل من 0.01٪ تمدد شعاعي تحت حمل كيميائي مستمر—وهي عوامل رئيسية في منع التسرب ضمن أنظمة الغاز ذات النقاء العالي.

تحليل مقارن: PTFE مقابل FEP مقابل PFA في أنظمة توصيل السوائل

رغم أن مادتي FEP وPFA تتمتعان بمقاومة كيميائية مشابهة، فإن مادة PTFE تتغلب عليهما من حيث المتانة الميكانيكية:

| الممتلكات | PTFE | إطار العمل | PFA |

|---|---|---|---|

| الحد الأقصى لدرجة الحرارة المستمرة | 260°م | 200 درجة مئوية | 260°م |

| مقاومة التشقق تحت الإجهاد | 200 رطل/بوصة² | 120 رطل/بوصة² | 180 رطل/بوصة² |

| نفاذية أيون الكلوريد (Cl–) | 0.001 غ/ساعة | 0.15 غ/ساعة | 0.03 غ/ساعة |

يُبلغ مصنعو المعدات الأصلية لأدوات أشباه الموصلات أن أنابيب PTFE تتطلب استبدالًا أقل بنسبة 67٪ مقارنةً بـ FEP في بيئات غاز الكلور، مما يبرز موثوقيتها على المدى الطويل.

متطلبات النقاء العالي والتحكم في التلوث باستخدام أنابيب التيفلون

دور مادة PTFE الافتراضية في تلبية معايير نقاء أشباه الموصلات

تتخلص راتنجات PTFE المصنوعة من مواد أولية من الشوائب المزعجة الموجودة في المواد المعاد تدويرها، وتخفض عدد الجسيمات إلى أقل من خمسة جسيمات لكل لتر في تلك الأنظمة الغازية فائقة النقاء. وفي الواقع، تجتاز الأنابيب الناتجة المعايير المطلوبة SEMI F81 لأغراض أشباه الموصلات، حيث تحصر أيونات المعادن عند مستويات تقل عن عشرة أجزاء في البليون. وعند تصنيع هذه الأنابيب في غرف نظيفة من الفئة ISO Class 4 باستخدام عمليات البثق، فإنها تقلل الجسيمات السطحية بنحو ثلاثة أرباع تقريبًا مقارنةً بالتقنيات الصناعية القياسية. ويجعل ذلك من هذه الأنابيب الخيار المثالي للتطبيقات التي قد يتسبب فيها أدنى تلوث بمشاكل كبيرة.

أداء تبخر الغازات من أنابيب التفلون عالية النقاء في البيئات المفرغة

يُظهر البوليتيترافلوروإيثيلين (PTFE) فقدان كتلة إجمالي أقل من 0.1٪ وفقًا لاختبار ASTM E595، ما يجعله أحد البوليمرات الفلورية ذات التبخر المنخفض للغاية المتوفرة حاليًا. تمنع هذه الخاصية تكوّن بخار الماء على الشرائح أثناء عملية التصوير الضوئي وتدعم التشغيل المستقر عند ضغط أقل من 10 -6تور في أنظمة التصوير الضوئي المتقدمة باستخدام الأشعة فوق البنفسجية الممتدة (EUV).

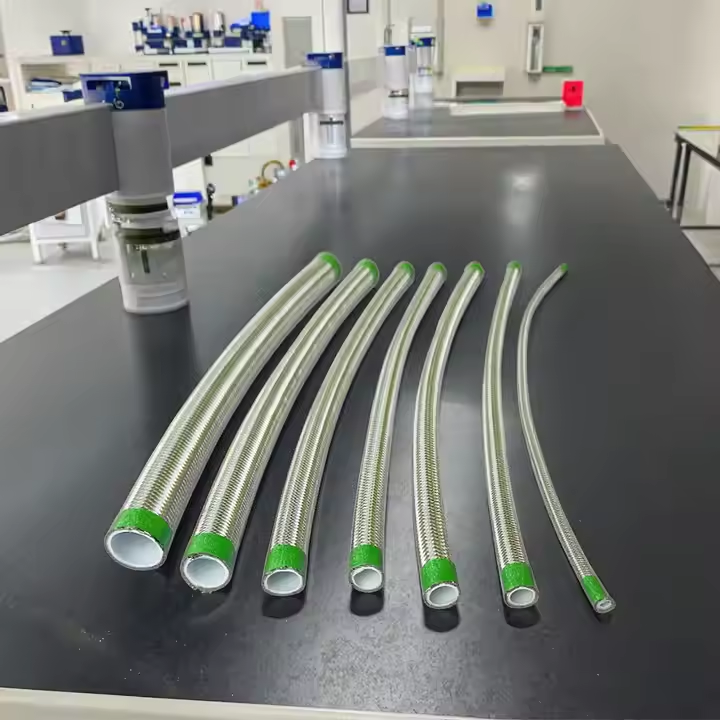

تركيبات أنابيب التفلون فائقة النقاء لتقليل مخاطر التلوث

تحتوي حزم خطوط البوليتيترافلوروإيثيلين (PTFE) المدمجة مصنعياً مع وصلات ملحومة دائرية على نقاط تسرب محتملة أقل بنسبة 92٪ مقارنةً بالأنظمة المجمعة ميدانيًا. وبفضل الأسطح الداخلية المصقولة كهربائيًا والتي تحقق خشونة سطحية (Ra) أقل من 0.3 ميكرومتر، فإن هذه التركيبات تقلل من المواد الكيميائية العالقة في خطوط السوائل – وهي خاصية ضرورية لتصنيع العقدة 3 نانومتر، حيث يمكن أن تؤدي عيوب بحجم 15 نانومتر إلى المساس بإنتاجية العملية.

دراسة حالة: تقليل معدلات عيوب الشرائح باستخدام خطوط سوائل قائمة على البوليتيترافلوروإيثيلين (PTFE)

خفضت شركة صهر من الدرجة الأولى عيوب الاستبعاد الحافة بنسبة 37٪ بعد استبدال خطوط النقل السيليكونية بأنابيب التفلون عالية التدفق. وأكد تحليل الأشعة السينية المبعثة للطاقة إزالة الملوثات العضوية السيليسية، مما وفر 2.3 مليون دولار شهريًا من رقائق الهدر خلال فترة إنتاج مدتها 18 شهرًا.

الاستقرار الحراري والثبات الميكانيكي لأنابيب التفلون

مرونة درجة الحرارة في تطبيقات عملية الترسيب الكيميائي بالطور البخاري والانتشار

يحافظ البوليتيترافلوروإيثيلين (PTFE) على سلامة هيكله حتى 260°م باستمرار، مع تحمل قصير الأمد يصل إلى 300°م، بما يتماشى مع المتطلبات الحرارية لغرف الترسيب الكيميائي بالطور البخاري التي تعمل عند حوالي 280°م. وتمنع روابطه المستقرة بين الكربون والفلور تحلل البوليمر حتى بعد 5000 ساعة من التعرض للحرارة العالية، مما يضمن أداءً ثابتًا عبر دورات التشغيل المتكررة.

الثبات الأبعادي تحت التغيرات الحرارية المتكررة في بيئات الأدوات

يبلغ معامل التمدد الحراري للبولي تيترا فلورو إيثيلين (PTFE) حوالي 1.14 × 10⁻⁴ لكل درجة مئوية، وهو ما يقل بنسبة 60 بالمئة تقريبًا مقارنة بمعظم البوليمرات الفلورية الأخرى. تساعد هذه الخاصية في تقليل الانحراف الموضعي في أنظمة توصيل الغاز الدقيقة حيث تكون الدقة مهمة جدًا. عندما تتعرض المعدات لدورات منتظمة بين درجة حرارة الغرفة ودرجة حرارة قريبة من 250 درجة مئوية على مدار اليوم، فإن أنابيب التفلون القياسية عادةً ما تشهد تغيرات أبعاد أقل من نصف جزء من عشرة بالمئة بعد تشغيلها لمدة عام كامل. توفر هذه الثباتية فرقًا كبيرًا في منع التسرب الصغيرة عند الختم الفراغي، وهي نقطة تكتسب أهمية بالغة في الحفاظ على الظروف المناسبة داخل الحجرة أثناء عمليات الإنتاج الكبيرة، حيث يمكن أن تؤدي الأعطال الصغيرة إلى مشكلات كبيرة لاحقًا.

المرونة التصميمية وتكامل النظام لأنابيب التفلون في أدوات أشباه الموصلات

يدعم أنبوب الـ PTFE التكامل الفعال في معدات أشباه الموصلات الحديثة بفضل تركيبته الفريدة من المرونة، والمقاومة الحرارية، والتوافق مع الأتمتة.

تشكيل وتوجيه مخصص للأنابيب البلاستيكية (تيفلون) في معدات أشباه الموصلات المدمجة

تتيح قدرة التفلون على التشكيل البارد إمكانية التعامل مع الانحناءات الضيقة جدًا، أحيانًا بشعاع لا يزيد عن خمسة أضعاف القطر، دون أن تنثني أو تشوه. وهذا يمكّن المهندسين من توجيه الأنابيب بدقة عبر الإعدادات الصناعية المزدحمة حيث تكون المساحة محدودة. ونتيجة لذلك، تقل الحاجة إلى الوصلات الإضافية التي قد تسمح بدخول الملوثات إلى النظام، كما يُحافظ على قطر الأنبوب الداخلي ثابتًا حتى في الترتيبات المعقدة ثلاثية الأبعاد. يستفيد العديد من مصنعي المعدات من حقيقة أن مادة البولي تيترا فلورو إيثيلين (PTFE) لا تحتفظ بالشكل السابق لها، مما يمكنهم من تمرير خطوطهم حول الأجزاء الحساسة التي قد تنصهر أو تتدهور في الظروف العادية. وكل هذا يعمل بكفاءة حتى عند درجات حرارة تصل إلى حوالي 260 درجة مئوية، وبالتالي لا يحدث انخفاض في الأداء رغم ارتفاع الحرارة.

التوافق مع الختم الآلي والوصلات وأساليب الأدوات الوحداتية

تعمل أنابيب البولي تيترا فلورو إيثيلين (PTFE) بشكل جيد جدًا مع وصلات الضغط القياسية من نوع Swagelok، وكذلك مع أنظمة التجميع الروبوتية، لأنها تحافظ على سماكة جدار موحدة للغاية طوال عملية التصنيع، وعادةً ما تكون ضمن نطاق ±0.01 مم. كما أن المادة تتميز بقيمة ضغط انضغاطي منخفضة جدًا، حيث تظل أقل من 15% حتى عند التعرض لضغوط تبلغ حوالي 1000 رطل/بوصة مربعة. وهذا يعني أن الوصلات تبقى مشدودة وخالية من التسرب لآلاف الدورات الحرارية، وهو أمر بالغ الأهمية في التطبيقات القائمة على المنصات المعيارية التي يكون فيها الاعتماد على الموثوقية أمرًا حاسمًا. وعندما يصمم المهندسون أنظمة شفة متقدمة تدمج أنابيب PTFE مع ختم Kalrez داخل أدوات التجميع، لاحظوا حدوث شيء مذهل أثناء عمليات نقل الرقائق الآلية. فقد تراجعت أحداث توليد الجسيمات بشكل كبير بنسبة تقارب 82% مقارنةً بالبدائل البوليمرية الصلبة، وفقًا لتقرير معايير SEMI للعام الماضي.

قسم الأسئلة الشائعة

ما الاستخدامات الشائعة لأنابيب التفلون في تصنيع أشباه الموصلات؟

تُستخدم أنابيب التيفلون في التعامل مع السوائل في تصنيع أشباه الموصلات بسبب خصائصها غير اللاصقة ونقاوتها العالية. وتضمن هذه الأنابيب أقل التصاق ممكن للجسيمات، وتقلل من التلوث، وتحافظ على نقاء النظام.

لماذا يُفضّل استخدام البولي تيترافلوروإيثيلين (PTFE) على مواد أخرى مثل FEP وPFA؟

يُفضّل البولي تيترافلوروإيثيلين (PTFE) لتميّزه بالمتانة الميكانيكية الأعلى، ومقاومة درجات الحرارة العالية، وانخفاض نفاذية المواد الكيميائية مقارنةً بـ FEP وPFA، ما يجعله أكثر موثوقية في البيئات الكيميائية القاسية.

كيف يساهم البولي تيترافلوروإيثيلين (PTFE) في الحفاظ على معايير الغرف النظيفة؟

تساعد الطاقة السطحية المنخفضة والخصائص الكارهة للماء في مادة البولي تيترافلوروإيثيلين (PTFE) في الحفاظ على بيئات فائقة النظافة من خلال منع التصاق الجسيمات وتقليل مستويات التلوث في الغرف النظيفة.

ما الدور الذي يؤديه البولي تيترافلوروإيثيلين (PTFE) في تقليل عيوب تصنيع أشباه الموصلات؟

يمنع البولي تيترافلوروإيثيلين (PTFE) تراكم الجسيمات والتفاعلات الكيميائية غير المرغوبة أثناء عمليات نقل السوائل، مما يقلل بشكل كبير من معدلات العيوب في عمليات تصنيع أشباه الموصلات.

هل يمكن لبولي تيترافلوروإيثيلين (PTFE) أن يتحمل درجات الحرارة والضغوط القصوى؟

نعم، يحافظ بولي تيترافلوروإيثيلين (PTFE) على خواصه ضمن نطاق واسع من درجات الحرارة (من -70°م إلى 260°م) والضغوط العالية، مما يجعله مثاليًا للتطبيقات الصعبة مثل الترسيب الكيميائي للبخار.

جدول المحتويات

- الخصائص غير اللاصقة لأنابيب التفلون في التعامل مع السوائل في صناعة أشباه الموصلات

- المقاومة الكيميائية ومتانة أنابيب PTFE في العمليات القاسية

- متطلبات النقاء العالي والتحكم في التلوث باستخدام أنابيب التيفلون

- الاستقرار الحراري والثبات الميكانيكي لأنابيب التفلون

- المرونة التصميمية وتكامل النظام لأنابيب التفلون في أدوات أشباه الموصلات

-

قسم الأسئلة الشائعة

- ما الاستخدامات الشائعة لأنابيب التفلون في تصنيع أشباه الموصلات؟

- لماذا يُفضّل استخدام البولي تيترافلوروإيثيلين (PTFE) على مواد أخرى مثل FEP وPFA؟

- كيف يساهم البولي تيترافلوروإيثيلين (PTFE) في الحفاظ على معايير الغرف النظيفة؟

- ما الدور الذي يؤديه البولي تيترافلوروإيثيلين (PTFE) في تقليل عيوب تصنيع أشباه الموصلات؟

- هل يمكن لبولي تيترافلوروإيثيلين (PTFE) أن يتحمل درجات الحرارة والضغوط القصوى؟